Flex Bond

Fiber-reinforced, ready-to-use, organic base coat in pasty form for thermal insulation boards

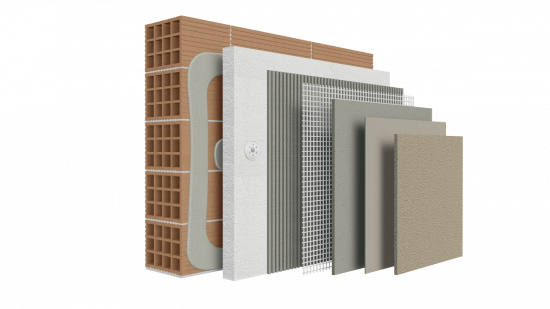

Flex Bond is a ready to use organic base coat in pasty form, for thermal insulation boards of Exterior Thermal Insulation Systems. It consists of polymer dispersion, PP fibers, natural aggregates and special additives. It also contains lightweight microspheres of 100% recycled expanded glass (Recycled Glass Technology) providing excellent applicability, surface uniformity and advanced mechanical properties. It has strong adhesion, great flexibility and resistance to impact stress.

It is classified as external render based on organic binders for use on external walls, ceilings and columns according to the standard EN 15824 and as part of certified external thermal insulation system CLIMAWALL® by BIOCLIMA® according to EAD 040083-00-0404, as base coat.

Advantages

- High impact resistance.

- Strong anti-cracking protection.

- High elasticity.

- Ready to use (cement free).

- No intermediate primer necessary.

Product Information

Packaging:25 KG

Shades:White

Certifications / Evaluations

Technical Info

Technical Information

0%

3-4 kg/m²

4-6 hours

Application - Tools

Download the files

How to Use

Flex Bond has very good adhesion on thermal insulation boards (expanded polystyrene, extruded polystyrene, mineral wool, etc.), but also on all standard substrates such as concrete, bricks, plaster, cement blocks, cement boards, plasterboard, etc. The application substrate must be stable, flat, free from loose and foreign bodies, such as e.g. residues of mud, plaster, paints, oils, etc. and without large cracks. On highly absorbent surfaces (e.g. aerated concrete, gypsum board) priming is recommended using Eco Dur Aqua micromolecular acrylic primer by KRAFT PAINTS.

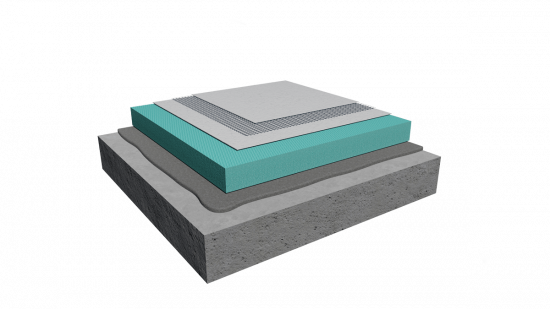

The surface of the thermal insulation boards should be uniform and even. Αpply, with a stainless steel toothed spatula, a layer of Flex Bond on the thermal insulation boards and immediately immerse the anti-alkaline fiber glass mesh in it. The surface of base coat is flattened and smoothed using the smooth side of spatula.

Overlap of strips of the base layer grid should be about 10cm. The mesh grid should be completely covered by Flex Bond. Final thickness of the layer shall be 2 - 3 mm.

Immediately after the application, the tools must be cleaned with warm water and soap or a detergent solution. Remove as much material as possible from tools before cleaning.