Mineral wool: Features, uses and fire protection

Mineral wool overview

Mineral Wool (MW) is classified as inorganic fibrous material. It is made from amphibolite metamorphic rock. This is heated to 1500°C, then it is enhanced by minerals such as dolomite and bauxite. Via centrifugal processing, the viscous material mass is ejected in the form of thin fibers, whose diameter is in the order of 4-5μm.

These fibers are bonded by way of special heat-adhesive resins.

In fact, where necessary, special waterproofing additives are injected during the production of thermal insulation boards from mineral wool fibers. Thus, the end product becomes moisture resistant (in the case of exterior thermal insulation applications, for instance). It can be produced in several variants: rolled fleece, fleece reinforced by metal grid or plate, standard or reinforced thermal insulation boards, pre-formed pipe sheaths, special soundproofing panels, etc.

Mineral wool available in the Hellenic Market should be certified according to European Standard ΕΝ 13162, pursuant to European Council EU Regulation (CPR 305/2011) for the adoption of harmonized product trading terms in the building construction sector.

Mineral wool characteristics & uses

Mineral wool is an excellent thermal insulation material (having low thermal conductivity coefficient λ: 0.035 – 0.040); it is a fireproof material (class A1 according to European Standard ΕΝ13501-1), exhibits excellent transpiration and also superior soundproofing properties. Taking also into account the broad range of forms and qualities available in the market and its ease of installation, the scope of application of mineral wool is significantly expanded: drywall building systems, interior or exterior building thermal insulation, soundproofing, fire protection and many more on walls, ceilings or floors, suitable for indoor as well as outdoor applications.

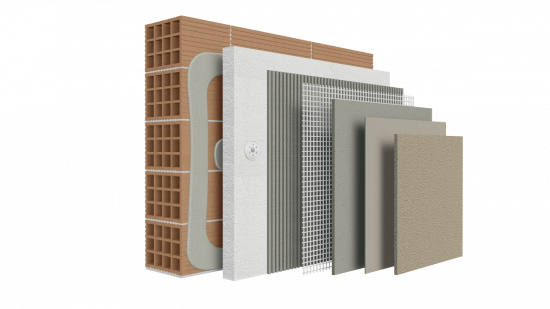

In exterior building thermal insulation applications in particular, heavy-duty mineral wool boards are used; these excel in terms of compression strength and density, at the same time providing the following attributes.

The main mineral wool advantages are the following:

- High thermal insulation protection (low thermal conductivity coefficient λ: 0.035– 0.036 W/mK)

- Satisfactory compression strength (there are several individual types according to compression strength)

- Moisture resistant, thanks to the specific waterproofing of fibers

- Excellent water vapor permeability, fully transpirating material (coefficient: μ=1)

- Easy to install yet resistant to cutting or abrasion compared to other thermal insulation materials (e.g. polystyrene).

- Heavier thermal insulation material compared to polystyrene

- Exceptional resistance at temperatures up to +750°C

- Immune to insects and rodents.

- Odourless material

- Non-deteriorated by chemical substances (excluding hydrochloric acid)

- Not sensitive to direct sunlight exposure (uncovered laying)

- It is considered to be non-combustible material (class Α1, according to ΕΝ 13501-1)

- Remarkable soundproofing material

Mineral wool and reaction to fire: The degree of protection against fire afforded by our material

Fire is among the most disastrous risks that can harm any edifice, either residence, commercial or industrial building. Fire can cause severe damage to building structure or constituents, and apparently, its tenants too; it can also pose threats to the environment and to public safety. Hence, contractors need to employ suitable materials and systems that can prevent or retard the spreading of fire and smoke in emergencies.

Thermal insulation and the associated construction products - such as non-combustible mineral wool - contribute to fire protection. In particular, mineral wool is a material that decreases heat transfer between individual building components such as walls, floors, ceilings and sloping roofs. It can also offer sound deadening, transpiration and water repellency.

Do mineral wool insulation boards exhibit fire protection properties?

One of the most remarkable properties of mineral wool thermal insulation boards is the reaction to fire. Mineral wool thermal insulation boards are non-combustible and classified under Α1 class, according to European Standard ΕΝ 13501-1; this means that the material will not ignite, even if exposed to fire or excessive heat. Commonly, mineral wool fibers exhibit melting points above 1000°C which is far higher than most other thermal insulation materials. Hence, boards can withstand prolonged exposure to fire without losing their integrity or releasing toxic fumes.

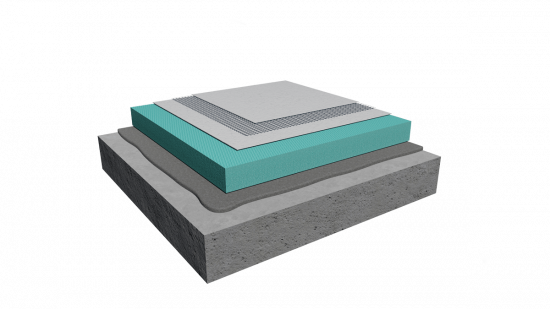

Mineral wool thermal insulation boards constitute an effective fire barrier, able to prevent or retard the spreading of fire and smoke in buildings. Mineral wool thermal insulation boards can be used in several parts of buildings, i.e. walls, floors, ceilings, sloping roofs, doors and divisions. It can be also used as fire prevention material for perimeter fire containment systems; in floor and wall penetrations; in construction expansion joints and other fire fighting applications.

Exterior thermal insulation: When to select mineral wool as thermal insulation panel

Thermal insulation materials aim to improve the thermal behavior of building structures.

A common attribute of all of them is superior resistance to heat transmission, thanks to the structure of their mass. As a principle, thermal insulation materials are those having a heat conductivity coefficient λ<0.1 W/mK.

The following is a basic classification of such materials:

- Organic materials of honeycomb structure, also named foam organic material

(e.g. expanded polystyrene, foam extruded polystyrene, polyurethane in foam or board form, phenolic foam, uric formaldehyde etc.)

- Inorganic fibrous material

(e.g. expanded polystyrene, foam extruded polystyrene, polyurethane in foam or board form, phenolic foam, uric formaldehyde etc.)

- Inorganic materials in granular for

(e.g. expanded perlite, pumice stone, vermiculite etc.)

- Organic fibrous or porous material

(e.g. wood fleece, cork, vegetal or animal materials etc.)

Under which conditions should apply to opt for mineral wool thermal insulation?

Mineral wool is an inorganic fibrous material, highly resistant to aging; stresses; extreme weather effects; vibration; and mechanical damage. It provides unique energy savings to the building, by way of an exterior thermal insulation system (BIOCLIMA® ClimaWall®), with impressive results in calorie consumption, thus it provides savings in cooling / heating bills as well as reduced residence wear and tear.

The selection of the appropriate thermal insulation material is determined according to specific project requirements. These are mainly dictated by geographical layout; weather effects that occur in each area and the particular conditions of the building itself. Areas having high transpiration needs often use mineral wool, since it is an especially water-permeable material.

Building fire protection requirements (e.g. for buildings close to forested areas or industrial areas with increased risk of accidents) also advocate in favour of non-combustible mineral wool as the thermal insulation material for the BIOCLIMA® ClimaWall® energy saving system.

As with all thermal insulation materials, mineral wool product thickness is also dependent upon the climate zone of the building.

Crews undertaking the application of exterior thermal insulation systems, should be experienced and skilled in the installation of systems containing mineral wool thermal insulation boards. The specific material requires special handling for installation by the crew in question, both with respect to the actual material (e.g. surface priming, cutting and sanding methods) as well as with respect to the fitter (e.g. masks should be used to avoid inhalation of minuscule fibers during installation). This parameter should be considered in the course of project design elaboration.