Graphite Polystyrene: Advantages, Disadvantages, and Applications

With significantly better thermal insulation properties compared to classic white expanded polystyrene, graphite polystyrene is worth the (slightly) higher cost. Here's what you need to know.

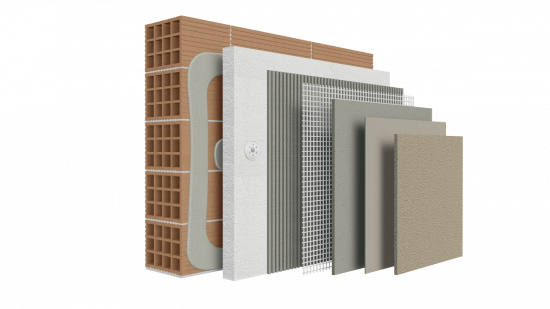

Graphite expanded polystyrene (Graphite EPS) is an advanced insulating material that combines expanded polystyrene (EPS) with graphite particles, enhancing its thermal insulation capacity. This material is widely used in the constructions, particularly in masonry, due to its excellent thermal insulating properties.

Graphite polystyrene is produced by injecting graphite particles into the mass of expanded polystyrene, giving the material its characteristic gray color (which varies depending on its compressive strength at 10% deformation). Essentially, this is an upgraded version of classic white expanded polystyrene, which, as we will see below, offers several advantages over it.

Graphite Polystyrene: Advantages

As the new generation of expanded polystyrene, graphite EPS enjoys all the benefits of white EPS, with some differences that make it qualitatively superior. Specifically:

Better Thermal Insulation: Graphite polystyrene offers up to 20% better thermal insulation performance compared to white EPS. This improvement is due to graphite's ability to enhance thermal conductivity while increasing thermal resistance. This is its main advantage over white EPS. Especially in areas with more demanding insulation needs (e.g., harsh winters or extreme summer heat), Graphite EPS is a recommended choice.

Improved Aging Resistance: Graphite EPS is highly resistant to aging and wear, maintaining its stability over time. It doesn't degrade, disintegrate, or decompose even after many years. This is important because Graphite EPS protects concrete from so-called "thermal shock" and premature aging, thereby extending the lifespan of a building’s structural framework.

In addition, it's a material that is completely environmentally friendly, 100% recyclable, and free from harmful chemical compounds. It is resistant to mold and bacteria, much like classic EPS, with which it shares similar properties—such as moisture resistance and water repellency, and ease of handling, installation, and transport.

Graphite Polystyrene: Disadvantages

Strictly speaking, there are no significant disadvantages. However, compared to white EPS, one factor should be considered:

Higher Cost: Graphite EPS is more expensive than conventional white EPS due to the addition of graphite and its more advanced production process. This could impact the overall cost of large-scale construction projects. However, for residential construction, the slightly higher price represents a balanced value-for-money investment.

Beyond that, although Graphite EPS is produced with self-extinguishing properties and contains flame retardants, it is usually classified under Euroclass E (as is white EPS), meaning it is a combustible material (but not easily flammable).

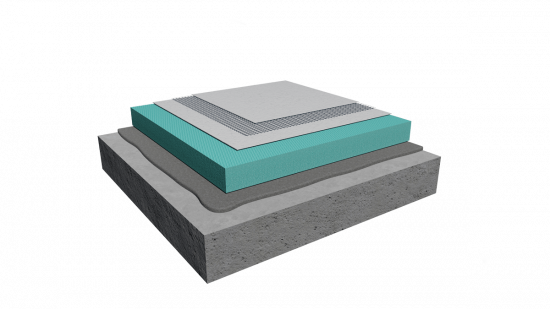

Graphite Polystyrene: Applications

Like standard EPS, graphite EPS can be used in a wide range of construction applications. Mainly in civil engineering projects for thermal insulation (external and internal), floors, ceilings/roofs, pilotis (open ground floors), rooftops, etc. It also finds use in decoration and architectural applications.