Expanded polystyrene: Benefits and applications

All you need to know about the popular thermal insulation material with the remarkable benefits and the wide range of application, as well as the top commercial products guaranteed to upgrade your home and any construction project.

Expanded polystyrene or the acronym EPS, is the same lightweight, stiff yet foamy thermal insulation material widely used in building and construction works, in homes and all sorts of buildings, and in food packaging as well. Due to its low cost and great benefits, EPS is widely used for more than half a century in the USA and Europe.

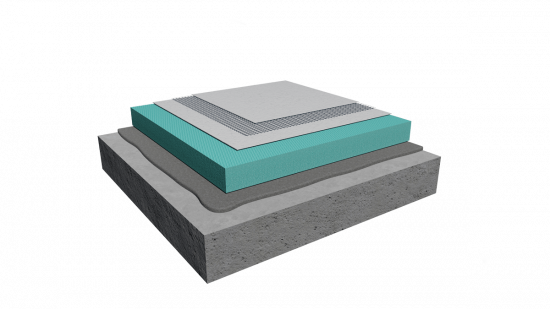

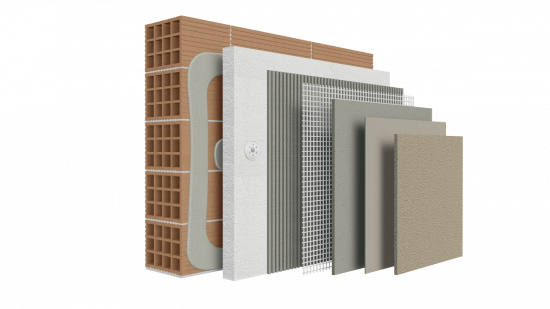

Expanded polystyrene boards consist of 98% entrapped air and are marketed in several thickness sizes to meet the requirements of different construction projects. The modern, advanced forms of this material expand its possible uses and constitute a benchmark for all construction projects that aim for efficient insulation and energy upgrade.

Extruded polystyrene is a material similar to expanded polystyrene, with similar properties. Furthermore, EPS Graphite by BIOCLIMA is among the best polystyrene types available in the Hellenic market. It contains graphite in its mass to assist in heat restriction (graphite particles are not infrared radiation - absorbing), supplementing EPS White, the tried and tested product by BIOCLIMA.