Everything You Need to Know About Extruded Polystyrene (XPS)

Advantages, disadvantages, and applications of a material that is steadily gaining ground and is among the top choices for thermal insulation.

Extruded polystyrene (XPS) is a synthetic thermal insulation material produced through a continuous extrusion process that forms panels (boards) with a homogeneous structure of closed, polygonal cells, minimizing the presence of air gaps between them.

These panels are used for insulation in foundations, basements, floors, roofs, terraces, external walls, and even in cold rooms and industrial facilities, as their compressive strength can reach up to 700 kPa (70 t/m² with 10% deformation) under distributed load. XPS is also used for insulating bridges and tunnels (in the same panel form), showcasing its wide range of applications and establishing it as a key component in modern construction.

On the market, XPS panels are available in various thicknesses, typically from 2 cm to over 20 cm, depending on the technical, aesthetic, and energy requirements of each project. They are commonly found in shades of blue, green, pink, yellow, etc.

Key Advantages

Extruded Polystyrene (XPS) offers several advantages that make it an excellent choice for thermal insulation in various construction applications. Its closed-cell structure gives the material:

- High Thermal Insulation Performance

XPS has a low thermal conductivity coefficient (λ = 0.033 W/m·K up to 7 cm thickness and 0.034 W/m·K for thicker boards), making it extremely efficient as an insulating material. This contributes to maintaining stable indoor temperatures and reducing energy costs for heating and cooling. - Moisture Resistance

Its closed-cell structure makes it almost impermeable to water and water vapor, preserving its insulating properties even in very humid conditions. This feature makes it ideal for use in high-moisture areas. - High Compressive Strength

XPS exhibits excellent compressive strength, withstanding significant loads without deformation. It is therefore ideal for use beneath floors, on roofs, and in areas with heavy traffic. - Resistance to Mold and Microorganisms

Its resistance to moisture minimizes the risk of mold and microbial growth, contributing to a healthier indoor environment and reducing maintenance needs. - Ease of Installation

XPS boards are lightweight and easy to cut and install, allowing for quick and efficient application. This reduces both labor costs and construction time. - Long-Term Performance

XPS retains its insulating properties over time, with a lifespan exceeding 50 years, making it a sustainable and cost-effective solution for long-term use.

Drawbacks and Limitations

Although XPS offers significant benefits as an insulation material, it also has some limitations that must be considered:

- Cost

XPS is generally more expensive than other insulation materials, such as expanded polystyrene (EPS) or mineral wool, which may be a constraint in low-budget projects. - Low Acoustic Insulation

Compared to mineral wool, both XPS and EPS offer limited soundproofing capabilities, making them unsuitable for areas requiring noise control. - Low Fire Resistance

XPS is classified as a Class E material regarding fire reaction (EN 13501-1), meaning it is not suitable for applications with high fire safety requirements. However, it is self-extinguishing and does not propagate flame. - Limited Flexibility

The rigid nature of XPS can make it less suitable for applications that require flexibility or adaptation to uneven surfaces. In such cases, sloped insulation boards with varying thicknesses may be preferred.

Drawbacks and Limitations

BIOCLIMA offers certified high-quality extruded polystyrene (XPS) insulation panels. In the XPS category, it provides three excellent solutions: XPS Etics GF, ClimaRoof KF-XPS, and ClimaRoof KF-XPS.

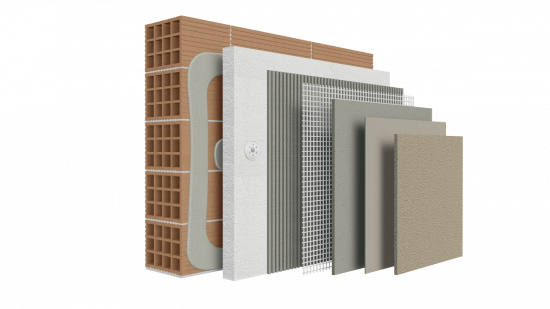

- XPS Etics GF is used as the insulating layer in the certified CLIMAWALL® External Thermal Insulation System (ETICS) for masonry walls.

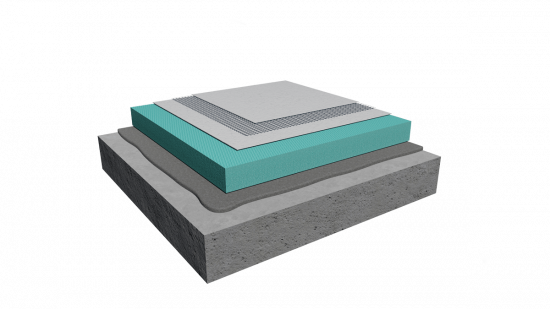

- ClimaRoof KF-XPS solutions are designed for use in the lightweight roof thermal and waterproofing system CLIMAROOF®, developed by BIOCLIMA®.