A complete guide on facades and terrace exterior thermal insulation systems

BIOCLIMA® focuses on products and systems that provide solutions for the energy upgrade of buildings. The company virtually changes perceptions regarding traditional structural materials and provides consumers with high added value.

Energy saving and thermal comfort afforded by exterior thermal insulation of facades as well as thermal and water insulation of terraces, are the essence of the BIOCLIMA® philosophy

In Greece, the building sector represents 41% of the overall end energy consumption, the majority of which is consumed by the household group and from the total energy consumption by the country’s households, around 65% refers to heating and cooling.

The above further reinforce the efficacy of adopting measures for the sufficient building thermal insulation and the reduction of the expenditures of households, in the winter as well as in the summer. Exterior thermal insulation is a substantial and effective solution that can be applied to existing as well as new buildings.

Facades and terrace thermal insulation

The notion of the External Thermal Insulation of a building construction is related to all these measures applied to the exterior of buildings that cover all structural components. This could be perceived as a “thermal mantle” that wraps all the exterior parts of a structure, offering energy protection and protection against environmental influences.

The use of thermal insulation materials aims at improving the thermal behavior of building structures. They share a common attribute: superior resistance to heat transmission, thanks to the structure of their mass. As a principle, thermal insulation materials are considered those having a heat conductivity coefficient λ<0.1 W/mK.

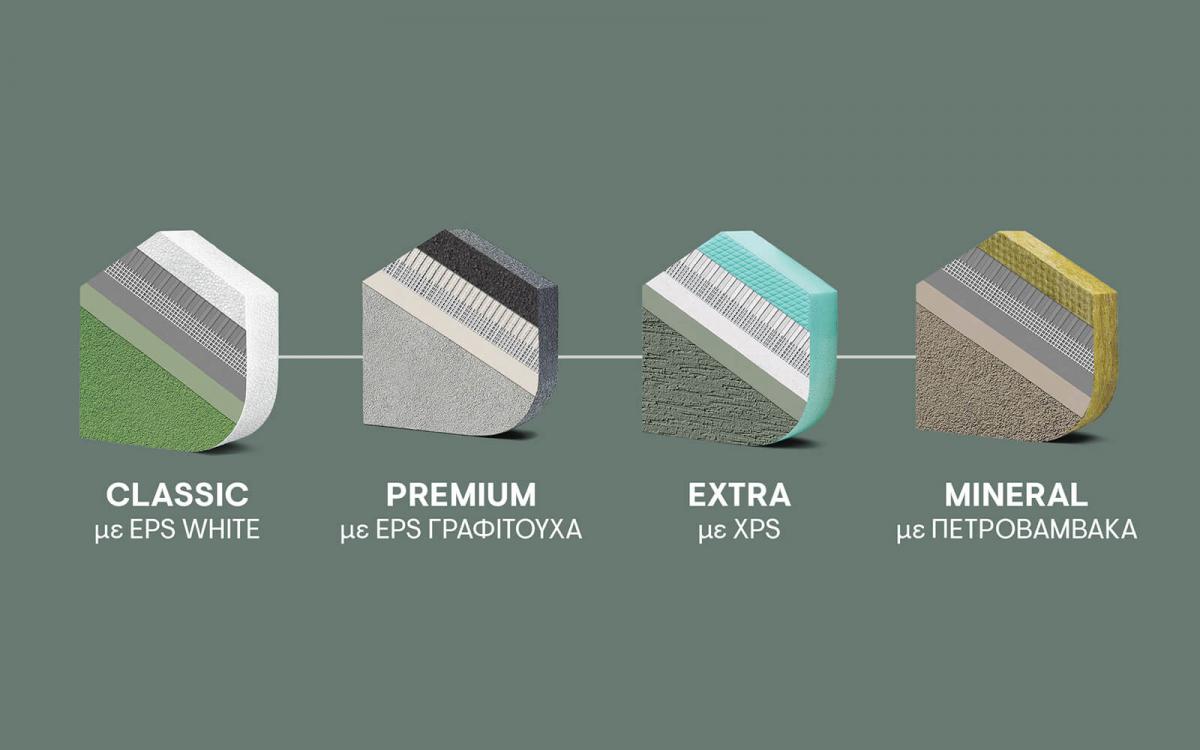

The following materials are largely used in external thermal insulation systems as well as thermal and water insulation applications in Greece, in order of market share and usage by the construction sector:

Expanded polystyrene (EPS)

Expanded Polystyrene (EPS): Expanded polystyrene is produced by the petrochemical industry and is part of the foamy synthetics.

Extruded polystyrene (XPS): Foamy Extruded Polystyrene (XPS) is a product closely related to expanded polystyrene, also produced by the petrochemical industry.

Mineral wool (MW): Mineral Wool (MW) is classified as inorganic fibrous material.

Flat roof and facade thermal insulation can be achieved in several ways, depending on structure type; climate conditions; materials used; and the functional need of the spaces they incorporate. The 3 most common ways are briefly described in the following.

- Thermal insulation installation on the exterior sides of a facade (external thermal insulation systems for facades)

- Thermal insulation installation on the interior side of a facade

- Thermal insulation installation in masonry cores

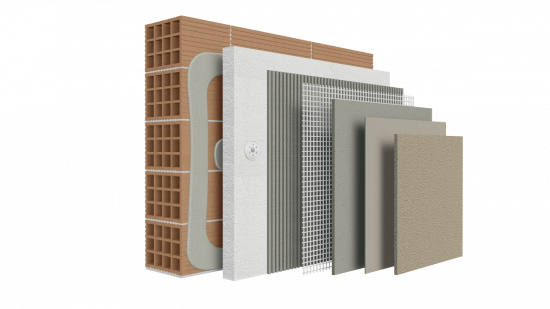

View all the subsystems of ClimaWall®

Advantages of thermal insulation systems

BIOCLIMA® ClimaWall® is a certified external thermal insulation system for facades and constitutes the most reliable choice - both in Greece and abroad. It consists of suitable successive layers of materials encompassing the masonry of the edifice, simultaneously offering the following:

- Energy upgrade (thermal insulation)

- Protection against weather effects

- Protection against moisture penetration

- Anticracking protection of facades

- Stylish finish allowing a multitude of decorative options

- Enhanced fire protection

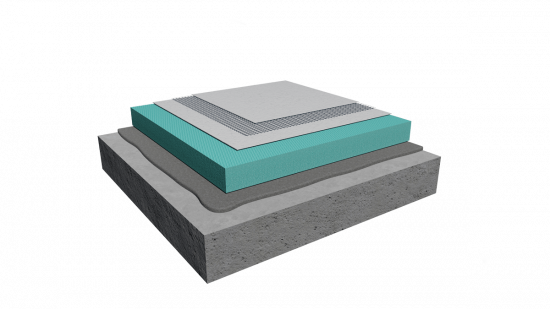

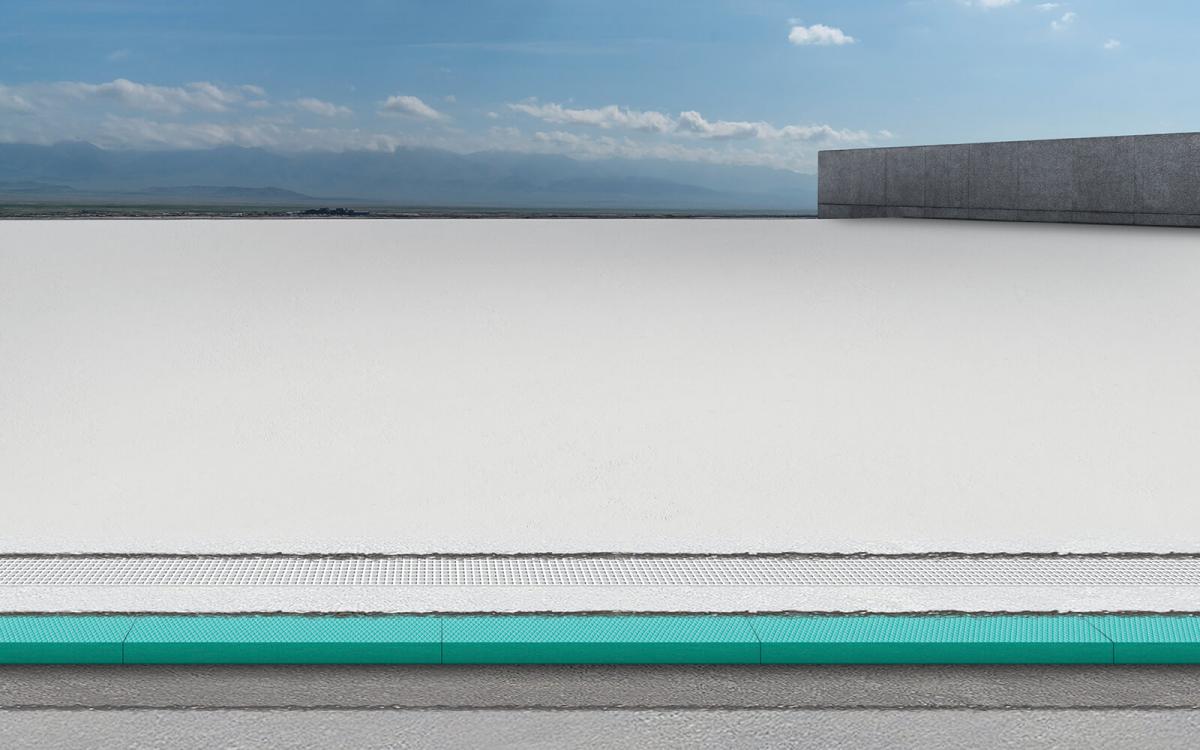

BIOCLIMA® ClimaRoof® is a comprehensive lightweight, thermal & water insulation system for flat roofs (terraces). It constitutes a series of thermal insulation construction product layers, bonding and waterproofing which are laid in discreet layers on building roofs, offering proven thermal and water protection.

Combines the following 4 main features:

- Thermal insulation protection, using FIBRAN extruded polystyrene

- Dual water insulation (in 2 levels: above and below the thermal insulation material) using specially designed single or twin-component mortars

- Light burden over terrace loads (indicatively, 18-20Kg/m2)

- Ability to create or correct drain gradients on the surface of the terrace

Constitutes an ideal solution for building terraces and, generally, horizontal exterior surfaces that need thermal / water insulation, since several advantages result from its application, such as:

- Thermal comfort throughout the year

- Excellent dual water insulation

- Excellent adhesion

- Limited application thickness

- Ability to create drainage gradients

- Ability to create a decorative finish

- Smart & affordable choice

- High mechanical resistance and satisfactory access

- High water vapor permeability and water repellency

What to look out for during the application

Main conditions for ClimaWall® thermal insulation application

- Systems should not be applied under rain or strong wind.

- When cured, applied materials and renders should be protected against rain, frost, strong wind and direct sunlight, at least for 72 hours.

- Before commencement of exterior thermal insulation system application, the following must be ensured:

- all works must be completed, as well as eventual terminals (e.g. for lightning rods, for drainage attachment, sat TV fixing, etc.) related to hydraulic and electrical installations on building facades

- suitable support mountings must be installed in case air-conditioning units or awnings need to be installed

- marble skirts and sub-frames need to be installed (optional and depending on the phase of sequence of works between installers)

- terrace and cantilever (balcony) sealing works must be completed, as, during thermal insulation works, penetration of moisture is possible, with adverse consequences.

In any case, particular attention should be placed on temperature - humidity ambient conditions (both current and imminent, taking into account weather reports). The ambient limits specified in product packaging should be observed.

Conditions for ClimaRoof® application

- The minimum thickness of thermal insulation is specified according to the energy study and eventual construction restrictions with respect to raising the terrace. Commonly, the minimum thickness of thermal insulation material required is between 60 and 100 mm, depending on the climate zone where the building is situated.

- It is necessary to check gradients and flatness of the substrate; this is carried out by spirit level all over the surface of the terrace, or by Laser instrument.

- The spirit level used is between 1 to 3 m long; it must be in contact with the substrate and its elongated side is directed to the gutter. Then the bubble should offset to the side opposite of the gutter (except if the spirit level functions inversely). The final gradient should be suitable to avoid standing water and to allow water flow to the gutter, i.e. positive gradient is necessary at all times, a minimum 1%.

- A straight yard will need to be laid in case of a complex terrace with excessive unevenness, potholes or numerous gutters. Local black stains indicate standing water and the absence of correct drainage gradients. The above mentioned filter should be carried out carefully to decide the need for correction and the development of gradients, hence to correctly assess system cost.

- Level differences up to ±10 mm can be remedied using mortar ClimaRoof KF-1. Greater difference and on surfaces larger than the thermal insulation board size, can be compensated by thermal insulation boards thinner or thicker than the average thermal insulation to be used.

- It is necessary to provide for an expansion joint at the perimeter of the application and where the floor intersects with vertical components.

- It is necessary to create interior expansion joints on terraces whose surface exceeds 80m2, also depending on the geometry of the surface.

- Avoid application on substrate temperatures below 5oC or above 35oC.

- Avoid application when rain is imminent or under direct sunlight and strong wind.