Fundamentals of thermal insulation and indoor air quality

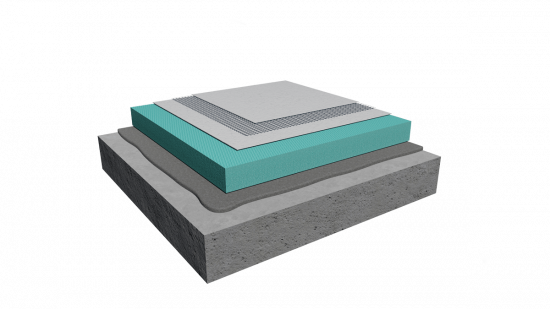

Building thermal insulation

All construction measures are applied to restrict the transmission of heat among indoor building spaces and the environment, as well as among indoor spaces having different thermal requirements.

Thermal bridges

Heat conductive material that penetrated or circumvented a thermal insulation system, allowing the transmission of heat through the path created by such material.

Thermal comfort

Conditions an individual experiences, where no temperature change is desirable. It is a subjective sensation, influenced by temperature, humidity, wind speed, clothes worn and human activity.

Α. REFLECTIVITY – COOL SURFACES

The consumption of energy of construction materials is directly dependent upon their technical properties; in fact, these determine thermal comfort in buildings.

- Materials used on exterior surfaces receive incident solar radiance, a part of which is absorbed by materials and the remainder is reflected. The quotient of reflected radiance to incident radiance on materials is called reflectivity; the quotient of radiance absorbed to incident radiance is called the absorption (a) of the material.

- Materials always emit heat radiation whose intensity is dependent upon the materials’ temperature and infrared radiation emission coefficient (e). The higher the emission coefficient, the easier the discharge of absorbed heat.

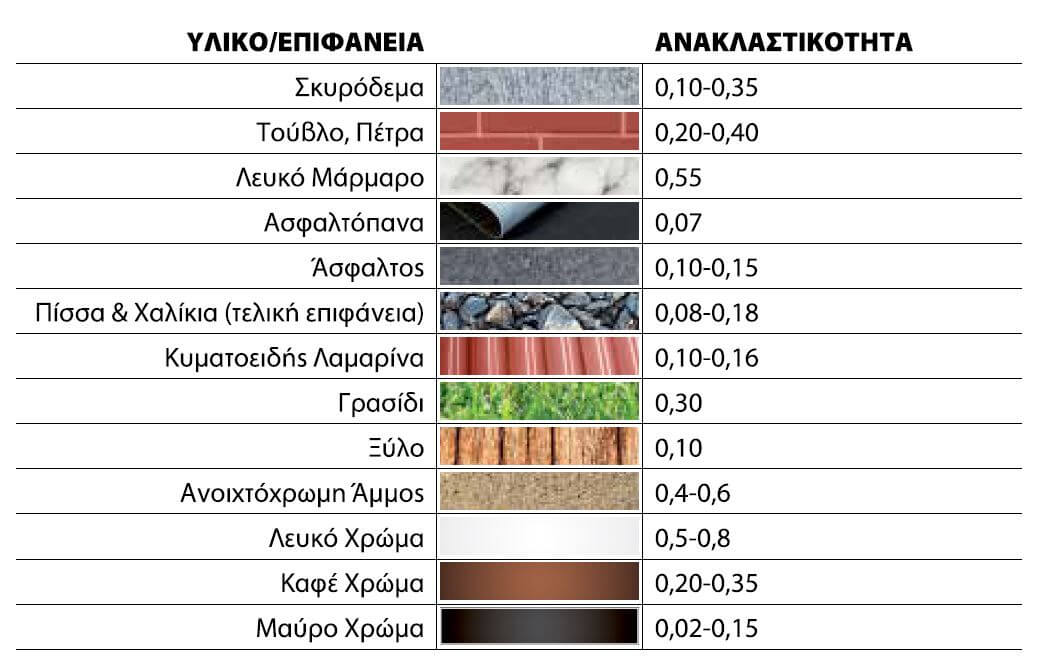

Using materials of high reflectivity directly contributes to the reduction of interior space temperature; thus, the use of light-colored surfaces significantly reduces the necessary operating loads of cooling units in buildings, resulting in remarkable financial gain. Table (Α) contains reflectivity values for various materials.

Table (Α)

MISCELLANEOUS MATERIALS REFLECTIVITY

Lately, materials are developed with advanced optical properties and increased reflectivity to radiance. These are the so-called cool materials. The term mainly refers to paint coatings, membranes etc.

Β. ΣΥΝΤΕΛΕΣΤΗΣ ΘΕΡΜΙΚΗΣ ΑΓΩΓΙΜΟΤΗΤΑΣ Λ

Σαν συντελεστής θερμικής αγωγιμότητας (λ) ορίζεται η ποσότητα θερμότητας που διέρχεται μέσα σε μία ώρα από ομοιογενές στρώμα υλικού πάχους 1m, όταν η διαφορά θερμοκρασίας μεταξύ δύο παράλληλων επιφανειών του στρώματος είναι 1 βαθμός Κελσίου.

The λ coefficient is measured in W/m.K or kcal/h.m. oC with the equivalence of 1kcal/h.m.oC = 1,163 W/m.κ. Thermal insulation materials are those with λ<0,1 W/m.κ. The lower the λ, the more heat-insulating the material is.

The factors influencing the selection of any thermal insulation material are the following:

- water vapour permeability

- flexibility

- hardness

- lifetime

- easiness of application and handling

- sensitivity to attacks by insects, rodents and microorganisms

- effect on the human body

- effect on the environment

- fire reaction

- noise behaviour

C. MAIN PROPERTIES OF THERMAL INSULATION MATERIALS

Temperature

The heat conductivity coefficient increases in proportion to temperature. This results in a reduction of the thermal insulation properties of the material.

Humidity

The heat conductivity coefficient increases in proportion to humidity. This dependence is apparent from the fact that λ of water and air is 0,57 W/m.Κ and 0,024 W/m Κ respectively. Fibrous materials (i.e. mineral wool, glass wool) are influenced by humidity, due to their structure; foamy materials (polystyrene, polyurethane) are affected to a minimal degree.

Solar radiation

Foamy insulation materials may suffer surface deterioration, reduction of their strength and loss of their thermal insulation properties.

Resistance to fire

Inorganic insulating materials exhibit exceptional behavior against fire, as opposed to most organic materials. These are considered to be self-extinguishing and cannot transmit flames.

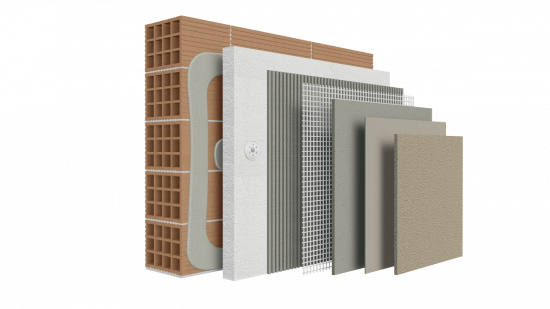

Mechanical strength

Insulating material resistance to compression or tension is a critical factor influencing insulating material installation in specific applications (load-bearing masonry, external thermal insulation systems). Organic foamy insulation materials exhibit better mechanical strength properties than inorganic fibrous materials.

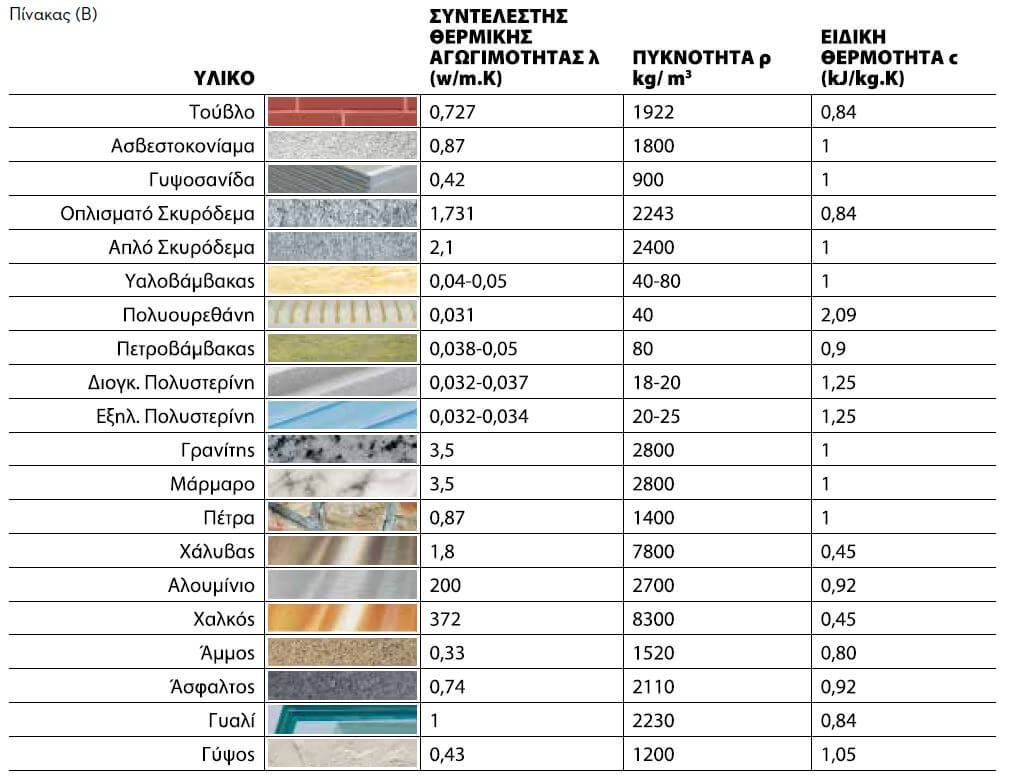

The following table (Β) lists the heat conductivity coefficient, density and specific heat of miscellaneous materials:

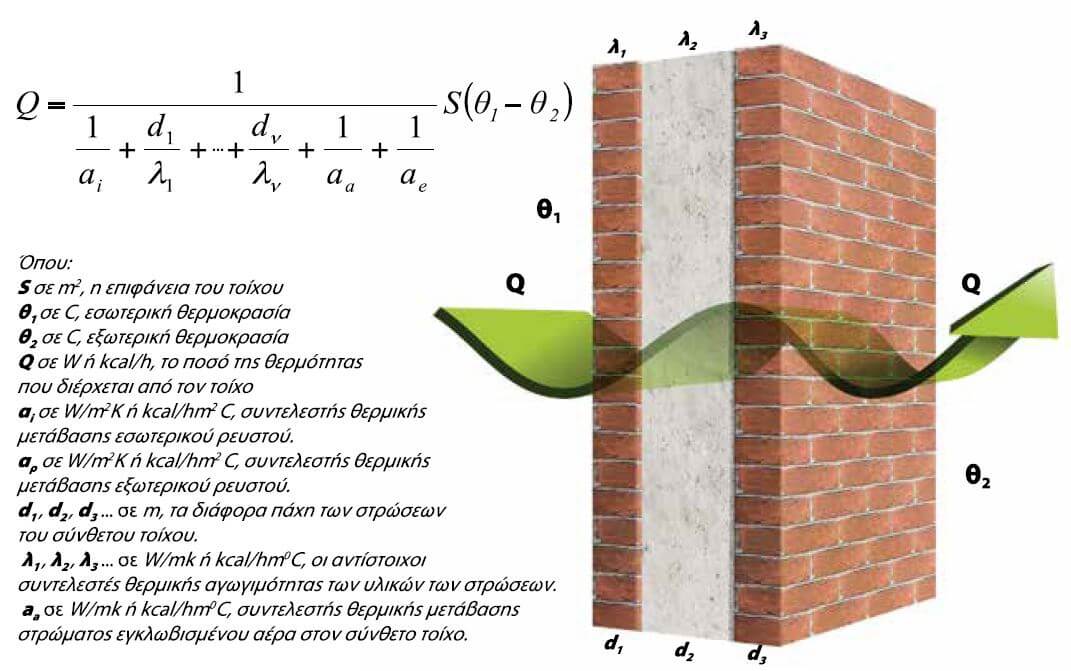

HEAT TRANSMISSION THROUGH A COMPOSITE WALL

Thermal energy Q, i.e. the quantity of heat transmitted in the unit of time, through a composite wall across its surfaces, is calculated through this formula:

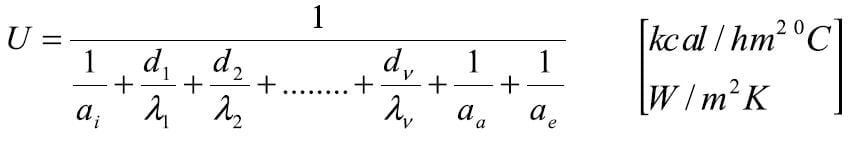

D. COMPOSITE WALL HEAT PERMEABILITY COEFFICIENT U (OR Κ)

This is the quantity of heat passing through a composite wall in one hour, being in a steady thermal state, with specific thickness and having 1m² surface, when the temperature difference of the air or the liquid that contacts the facings of the wall is equal to 1οC.

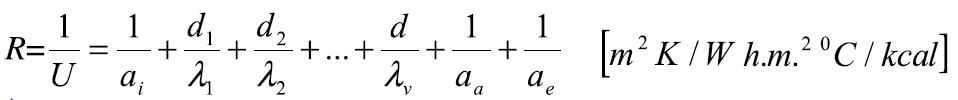

The inverse of coefficient U is called wall heat permeability resistance (R). It is a metric of its thermal insulation capability.

Hence

![]()

Ε. THERMAL CAPACITY OF ELEMENTS – THERMAL INERTIA

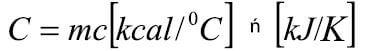

Function of the mass of structural components A material’s or component’s thermal capacity (C) is the ability of the same to store the heat received from the environment within its mass and release the same at a subsequent time. The specific heat of a material is the amount of heat required to increase the temperature of a mass equal to 1kg of the material by 10C; it is measured in kJ/kg.Κ or kcal/kg 0C or Btu/lb 0F.

The thermal capacity is proportional to the mass, or the density and the specific heat of the concerned material. This is calculated according to the following formula:

where C is the material’s thermal capacity; m in (kg) is the material’s mass; c kcal/kg 0C or kJ/kg.Κ is the material’s specific heat.

In particular

- Air exhibits the lowest thermal capacity, while water exhibits the highest.

- Steel’s thermal capacity is lower than water’s.

- Concrete thermal capacity is approximately 20% higher than stone and 50% higher than bricks.

Construction materials absorb and store heat when heated by the incident solar radiation on a building. Part of this heat is reflected; the remaining heat is converted into heat and absorbed by the building’s structural parts. The rate of heat absorption or release by any part is called thermal inertia and is influenced by the material’s thickness and thermal capacity.

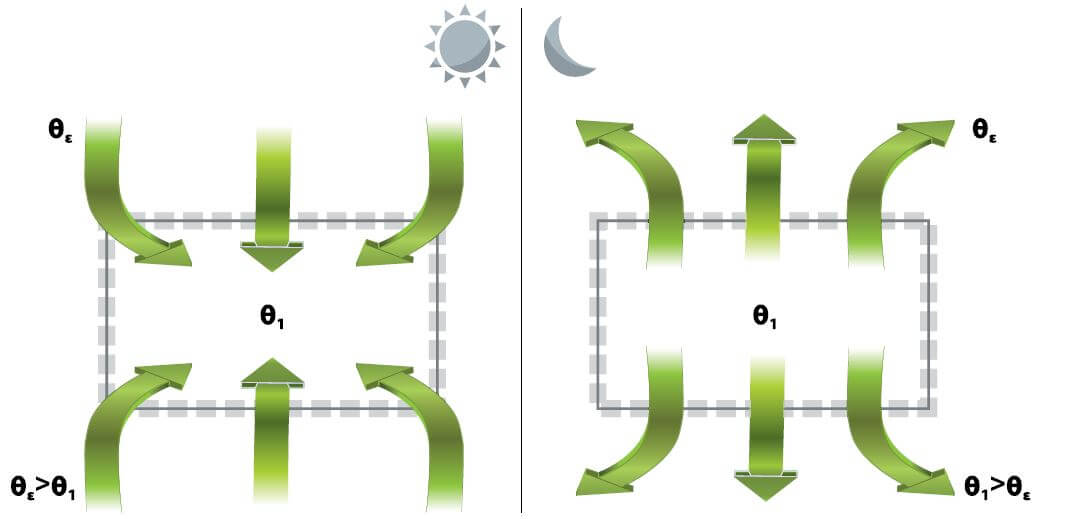

A significant quantity of solar radiation enters the building’s interior (through its openings) and heats the indoor air; the latter subsequently transfers heat by conduction to structural parts and other objects located in the building. The storage and feedback of heat contained in the parts is owed to the flow of heat from hotter to colder environments. During the day, the flow of heat is from outdoors to the interior; during the night - when indoor temperature is higher than outdoor - heat flows from the inside to the exterior.

To ensure proper building functioning, the use of high thermal capacity materials is of particular importance. The building acts as a heat accumulator, absorbing space heat in the summer, reducing indoor temperature. On the contrary, in the wintertime, the building stores the heat produced by the sun and other sources; this heat is released during the night to the interior, thus creating the sense of thermal comfort.

HEAT FLOW

CLIMATE ZONES

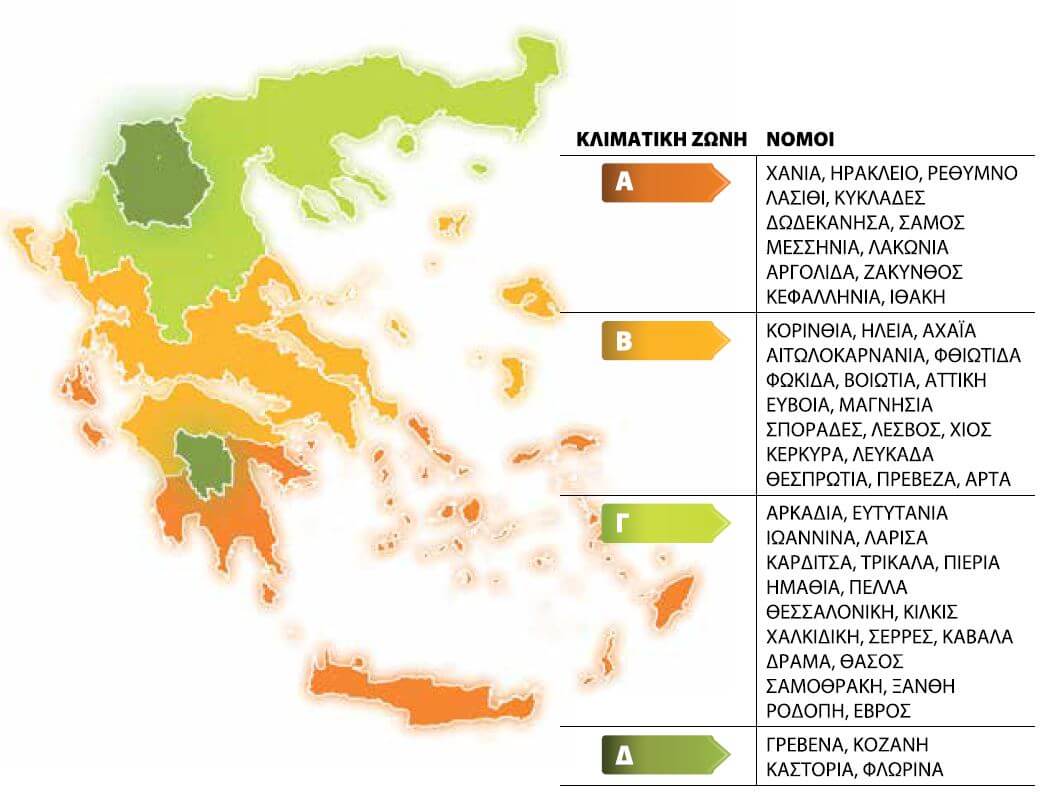

For the purposes of the KENAK (the Building Energy Efficiency Code) the Hellenic territory is divided into 4 climate zones, as shown in table (C) and schematically represented on the map.

Table C

HELLENIC PREFECTURE ADMINISTRATIONS BY CLIMATE ZONE

BUILDING SHELL

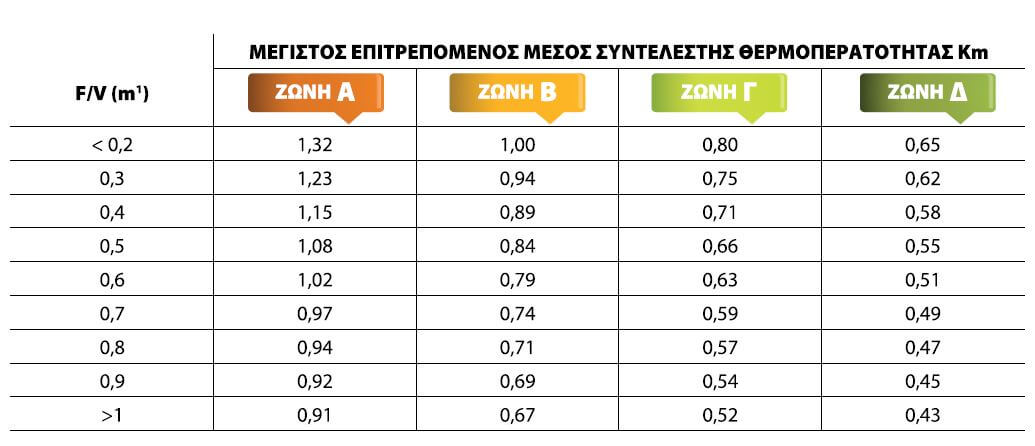

Regarding building shells and the structural parts indicated in table (D), the peak permissible heat permeability coefficients for the 4 climate zones of Greece are:

MAXIMUM ALLOWED COEFFICIENT

Heat permeability of structural parts for the 4 climate zones of Greece

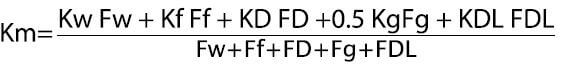

Lastly, regarding each building, the respective value of the average heat permeability coefficient Km (i.e. the number corresponding to building losses) shall not exceed the limits specified in table (Ε).

Hence:

(Where κw,Kf,KD,Kg,KDL the respective heat conductivity coefficients of surfaces, as shown in table (D), and Fw,Ff,FD,Fg,FDL are the corresponding surface areas).

Table E

MAXIMUM ALLOWED AVERAGE COEFFICIENT

of heat permeability Km (for the building) by climate zone

Where F is the total exterior building surface (m²), V the total volume of the structure (m3).

KENAK describes the method of calculating the maximum allowed average heat permeability coefficient.